●Used in situations where force measurement signals need to be converted into digital communication signals, standard analog output signals, and simple control

●Analog output signals can be selected from 4~20mA or 0~± 10 V

●The digital communication interface can be selected as RS485 or RS232

●Multiple filtering debugging modes make it easier to obtain target values

●Both power supply and signal have isolation processing, strong anti-interference ability, and more stable data acquisition and output

●LED displays real-time weight values, peaks, etc

●Comparable output, peak capture, peak comparison output

●Non weight calibration, TEDS automatic calibration

●High speed sampling (up to 1600 times), fast display speed

●The controller power supply adopts isolated DC24V ± 10% for safer and more stable power supply

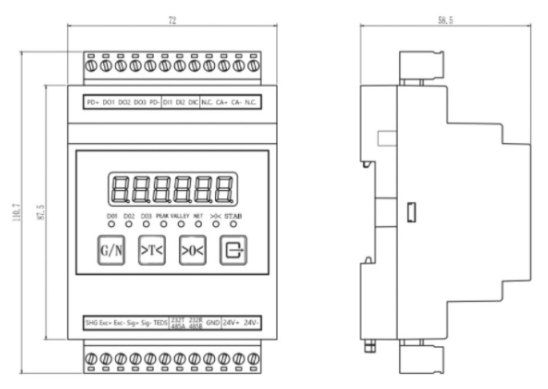

●Installation of 35mm standard industrial guide rail

● Application areas: automotive press fitting, automated assembly, 3C product testing, new energy product assembly, medical testing, robotics, mold assembly, and other industrial testing, measurement, and control systems.

| Display window | Low power LED display | Temperature drift to zero | ≤10 μ V/℃ |

| Output linearity | <0.01% | Excitation | 5 VDC |

| Comprehensive accuracy | Better than 0.01% | Power supply | 24 ±10% VDC |

| Acceptance sensitivity | ±30 mV/V | Overall Power Consumption | ≤8W |

| Input load | 1-8 350 Ω sensors | Interface | Isolated RS 232 / 485 |

| Output specifications | 4-20mA、0~±10V | Switching quantity | 2 switch inputs, 3-way switching output (OC) |

| Full scale temperature drift | ≤10 ppm/℃ | Operating temperature range | -40~85℃ |